In today's dynamic marketplace, enterprises are constantly striving to improve their operational efficiency and deliver exceptional customer experiences. Supply chain collaboration has emerged as a essential imperative in achieving these goals. By fostering robust relationships with suppliers, manufacturers, distributors, and retailers, firms can optimize their supply chain processes, resulting to significant performance improvements. A collaborative approach encourages information sharing, enabling all stakeholders to have a consistent view of the supply chain. This, in turn, minimizes delays, enhances inventory management, and expedites order fulfillment.

- Specifically, collaborative planning, forecasting, and replenishment (CPFR) initiatives can assist companies to accurately forecast demand and coordinate production schedules with actual customer needs.

- Additionally, collaborative logistics solutions can leverage technology to improve transportation routes, reduce delivery times, and reduce shipping costs.

- As a result, supply chain collaboration is not merely a practice but a fundamental business strategy that can fuel sustainable growth and market success.

Real-World Examples of Successful Supply Chain Collaboration

Supply logistics collaboration has become crucial for businesses to thrive in today's dynamic market. Numerous real-world examples showcase the immense benefits of seamless communication and coordination between vendors.

For instance, organizations like Walmart have built strong relationships with their suppliers, enabling them to optimize inventory management and reduce delivery periods. This collaborative approach has resulted in enhanced customer satisfaction and a strategic advantage.

Similarly, the automotive industry exemplifies successful supply chain collaboration through joint programs. Manufacturers often work closely with their component suppliers to develop innovative solutions and streamline production processes. This collaboration leads to faster time-to-market, reduced costs, and improved product quality.

A Roadmap for Efficient Supply Chain Collaboration

Achieving optimal supply chain performance hinges on fostering robust partnership among all stakeholders. A strategic framework provides a structured approach to harmonizing objectives, processes, and resources across the entire value network. Key components of such a framework include establishing clear communication protocols, implementing digital platforms, and cultivating mutual benefit among participating organizations. By embracing these principles, businesses can optimize their supply chains for greater efficiency.

- Leveraging real-time data to make proactive decisions.

- Fostering a culture of joint problem-solving throughout the supply chain.

- Prioritizing continuous innovation initiatives.

Unlocking Value: The Meaning and Impact of Supply Chain Collaboration

Supply chain collaboration is a transformative in today's dynamic business landscape. It involves fostering strong, strategic relationships between partners across the supply chain. By eliminating silos and improving information flow, organizations can achieve significant value.

Boosted efficiency, reduced costs, and enhanced customer satisfaction are just some of the primary advantages that result from effective supply chain collaboration. Moreover, it allows businesses to become more adaptable this post in the face of changing demands.

- Through collaborative initiatives, companies can optimize processes, share best practices, and identify potential risks and possibilities.

- Ideally, supply chain collaboration empowers organizations to deliver superior value to their customers, strengthening competitive position.

Building Stronger Networks: A Guide to Supply Chain Collaboration

In today's dynamic global marketplace, building robust supply chains is paramount. Successful organizations understand that true strength lies in forging collaborative partnerships with their suppliers and partners. Embracing collaborative practices can optimize operations, mitigate risks, and ultimately drive profitability. A well-structured supply chain network fosters visibility throughout the entire process, enabling efficient information flow and improved decision-making.

- Cultivating trust and open communication among supply chain stakeholders is crucial for building strong networks.

- Integrating technology solutions can automate processes, facilitate data sharing, and provide real-time visibility into operations.

- Creating clear goals and metrics allows for meaningful performance tracking and continuous improvement.

By prioritizing collaboration and adopting a holistic approach to supply chain management, enterprises can achieve long-term success in today's competitive landscape.

Strengthening Resilience Through Collaboration: Mastering Supply Chain Challenges

In today's dynamic global marketplace, supply chains face an increasing number of obstacles. From unforeseen events like natural disasters and geopolitical tensions to shifting consumer demands, businesses must thrive in the face of constant change. Collaboration has emerged as a crucial strategy for building robustness within supply chains.

By sharing information, resources, and expertise, companies can mitigate risks.

- For example, real-time monitoring across the supply chain enables foresight to address bottlenecks before they become critical

- Furthermore, collaborative procurement can diversify risk and ensure a more reliable flow of materials and products.

Ultimately, embracing collaboration as a core philosophy is essential for navigating the complexities of modern supply chains and building a more resilient business model.

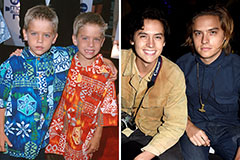

Dylan and Cole Sprouse Then & Now!

Dylan and Cole Sprouse Then & Now! Hailie Jade Scott Mathers Then & Now!

Hailie Jade Scott Mathers Then & Now! Matilda Ledger Then & Now!

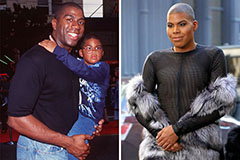

Matilda Ledger Then & Now! Earvin Johnson III Then & Now!

Earvin Johnson III Then & Now! Nancy Kerrigan Then & Now!

Nancy Kerrigan Then & Now!